Analysis of conventional flexible packaging combination

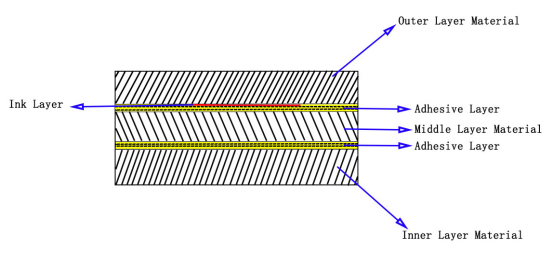

The word “compound” in flexible industry actually means “lamination”. That is to bind films of different properties together in a certain way, and sealed, so that to protect the content. The laminated structure of flexible packaging can be divided into many categories according to different combinations, so we cannot use only one system to describe different structures. However, the structures of conventional flexible packaging are often distinguished by its outer layer, middle layer, adhesive layer, inner layer. Typical three - layer composite structure is as shown in picture 1-1.

picture 1-1:

1. outer layer material

The material used in the outer layer is usually with properties such as good mechanical strength, heat-resisting, good printing performance, good optics performance, etc. Nowadays, the most commonly used materials for outer layer are PET, NY, BOPP, PAPER, etc.

Requirements and functions of outer layer material are shown as below chart 1-1.

Chart 1-1 Requirements and functions of outer layer material

Requirement | functions |

Mechanical strength | Tear growth resistance、shock resistance、friction resisting |

Barrier property | Moisture proof、air tightness、fragrance protectiveness、ultraviolet-proof |

Stability | Light resistance、oil resistance、 resistance to organic matter、heat resistance、cold resistance |

Processibility | friction、thermal shrinkage crimp |

Hygienic safety | Low-odor、non-toxic |

Others | Good printing performance、gloss、transparent、lightproof、whiteness |

2.middle layer material

Normally the material used in the middle layer is to enhance some property of laminated structure, such as barrier property, lightproof, fragrance protectiveness, strength, etc. Nowadays, the most commonly used materials for middle layer are AL、VMCPP、VMPET、PET、NY、KBOPP、KPET、KNOY, etc.

Requirements and functions of middle layer material are shown as below chart 1-2.

Chart 1-2 Requirements and functions of middle layer material

Requirement | functions |

Mechanical strength | Tensile strength、tear resistance、shock resistance |

Barrier property | |

Processibility | Double sides composite strength |

Others | transparent、lightproof |

3.Inner layer material

The most crucial and important function for inner layer material is its sealing performance, followed by its pressure resistance, drop performance and airtight performance. Nowadays, the most commonly used materials for inner layer are CPP, PE and its modified materials.

Requirements and functions of inner layer material are as shown in below chart 1-3.

4.Ink layer

The major function for ink layer is to achieve the transfer of graphic information and color reproduction, to some extent, it also helps to achieve the function of promotion. At the same time, the ink must be selected based on the packaging post-processing and product circulation conditions.

5.Adhesive layer

With the help of adhesive layer, two or more layers of material can be bonded together so that to make it a whole. The bonding strength between the adhesive layer and film material is an important indicator evaluating the internal performance of laminated films. Different packaging, according to the adhesive features, will have different tolerance requirements.

Composite packaging material is the use of general materials through the combination of technology to achieve product packaging. The function of the combined packaging material should be greater than that of the original packaging material. For example, when n types of material are combined, its function should be greater than the sum of the functions of several materials used separately before the combination. However, when the combination of the packaging materials cannot meet above requirement - the function of combined packaging material should be greater than the sum of the functions of several materials used separately before the combination, then this combination is a failure, or at least it’s meaningless and no point for combination.