Skin Packaging

- LD PACK

- China

- Meet, beef, fish, cheese and pasta or use in non-food packaging

- We have enough machinery and equipment for production to reach 350 tons per week.

- 3,000 KG

- 30 days lead time

Skin packaging provides a strong support for vsp packaging, high rigidity double-side printing, cooperate with the skin film provides a kind of special packaging solution. Cover layer use compostable film, environmentally friendly.

VSPB is high barrier paper laminate ideal for use in food industry for meet, beef, fish, cheese and pasta or use in non-food packaging.

Comply with the relevant requirement of EU/FDA/BFR for food packaging use.

SKIN PACKAGING

Place a product on a substrate material such as paperboard, then cover a heat vsp film over the product and the substrate, and drain the air inside so that the vsp film will cling tightly to the board and around the product.

Skin packaging, providing a strong support for vsp packaging, high rigidity double-side printing, is a kind of special packaging solution.

The cover layer we use is compostable film, which is environmentally friendly. VSPB, a high barrier paper laminate, is ideal to use in food packaging like meat, beef, fish, cheese and pasta, or use in non food packaging.

LD's skin packaging comply with the requirement of EU/FDA/BFR for food packaging use.

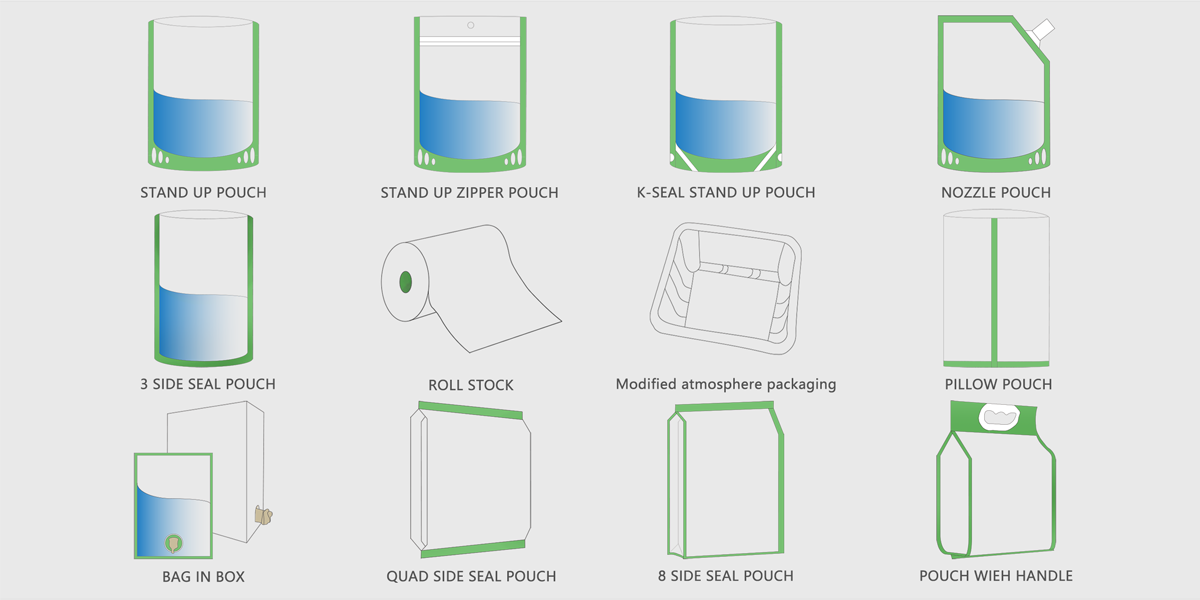

STYLE SELECTION

WORKING FLOW FOR BEFOR PRODUCTION

1 Provide us the detail information of the pouch, including use purpose, size, artwork, structure and thickness.

2Then we quote accordingly, we may quote many times for the best option for you.

3 After your confirmation on pricing, we will start working on the artwork processing.

4 Setting up the color standard

5Confirmation for both side to artwork and sign the contract.

6 You will need to prepay the cylinder (printing cost) and 40% advanced payment of the order.

7 Then we starting making the lovely flexible packaging for you.

Of course we will have certificates for helping you to get the idea how LD PACK worth to trust and worth to choose.

About LD PACK

ENTERPRISE STRENGTH

High production capacity,The production base covers an area more than 35,000 ㎡,Annual production can reach 25,000 tons.

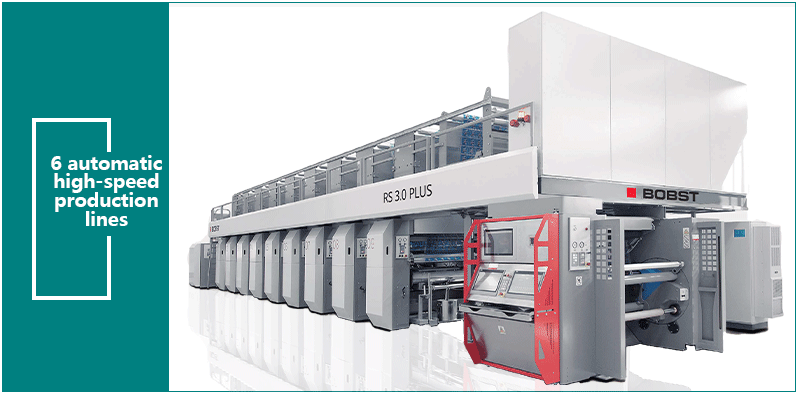

ADVANCED PRODUCTION EQUIPMENT

100,000-class GMPB brand new workshops.

6 automatic high-speed production lines.

STRONG TECHNOLOGICAL INNOVATIVE ABILITY

Obtain 9 invention patents.

Obtain 15 patents of utility model (including 1 international invention patent)

PERFECT AND STABLE QUALITY ASSURANCE

Professional inspecting equipment.

Quality-safety certification.

SUSTAINABLE DEVELOPMENT CONCEPT

Equip with specialized waste gas treatment to reduce the carbon emission.

FAQ

Are you a manufacturer?

Yes, we have more than 25 years experience in flexible packaging from 1990.Including Packaging bags, Plastic bag / Stand up Pouch/Spout bags/Ziplock bags/ Food Packaging Pouch/Stand up Pouch with spout/ Plastic pouch/Black ziplock Pouch/Cookie bag/Popsicle Packaging/Ziplock bags

What information should I let you know if I want to get a quotation?

- Bag shape

- Dimension: Length x width (+ bottom/side gusset)

- Material structure and thickness, surface handling

If you are not sure, please let me know the effect you want and we will suggest.

- Printing colors, please also provide the artwork if possible

- Quantity

When we create the artwork, what kind of format is available for printing?

- AI, PSD, CORELDRAW, PDF