Biaxial stretching of film

The production of biaxially stretched films typically involves two methods: flat film stretching and the double or triple bubble method. The general process of flat film stretching involves extruding a polymer from a machine, heating it until it melts, and then allowing the molten material to flow out of the die to form a thick sheet. This sheet is immediately quenched to solidify it. Within a specified temperature and speed range (high elastic temperature and stretching speed), the material is then stretched in both the longitudinal and transverse directions at a certain ratio. This stretching promotes the orderly arrangement of polymer chains or crystals along the plane direction. The stretched structure is then fixed in a taut or relaxed state (thermoforming). Subsequently, the material undergoes cooling and annealing treatments to produce biaxially stretched films. The flat film method can further be categorized into synchronous stretching or asynchronous stretching.

Synchronous stretching" refers to the process of simultaneously orienting and stretching the film in both the longitudinal and transverse directions on the same stretching machine. During this stretching process, the fast crystallization speed and high degree of crystallinity contribute to a significant improvement in the film's transparency. This method allows for the production of ultra-thin films. Practical experience in production confirms that if the orientation in both the longitudinal and transverse directions can be balanced, the mechanical properties of the film are relatively even. When the orientation in both directions is equal, the film exhibits isotropic properties, while if the orientation in one direction is greater than the other, the film's properties become anisotropic.

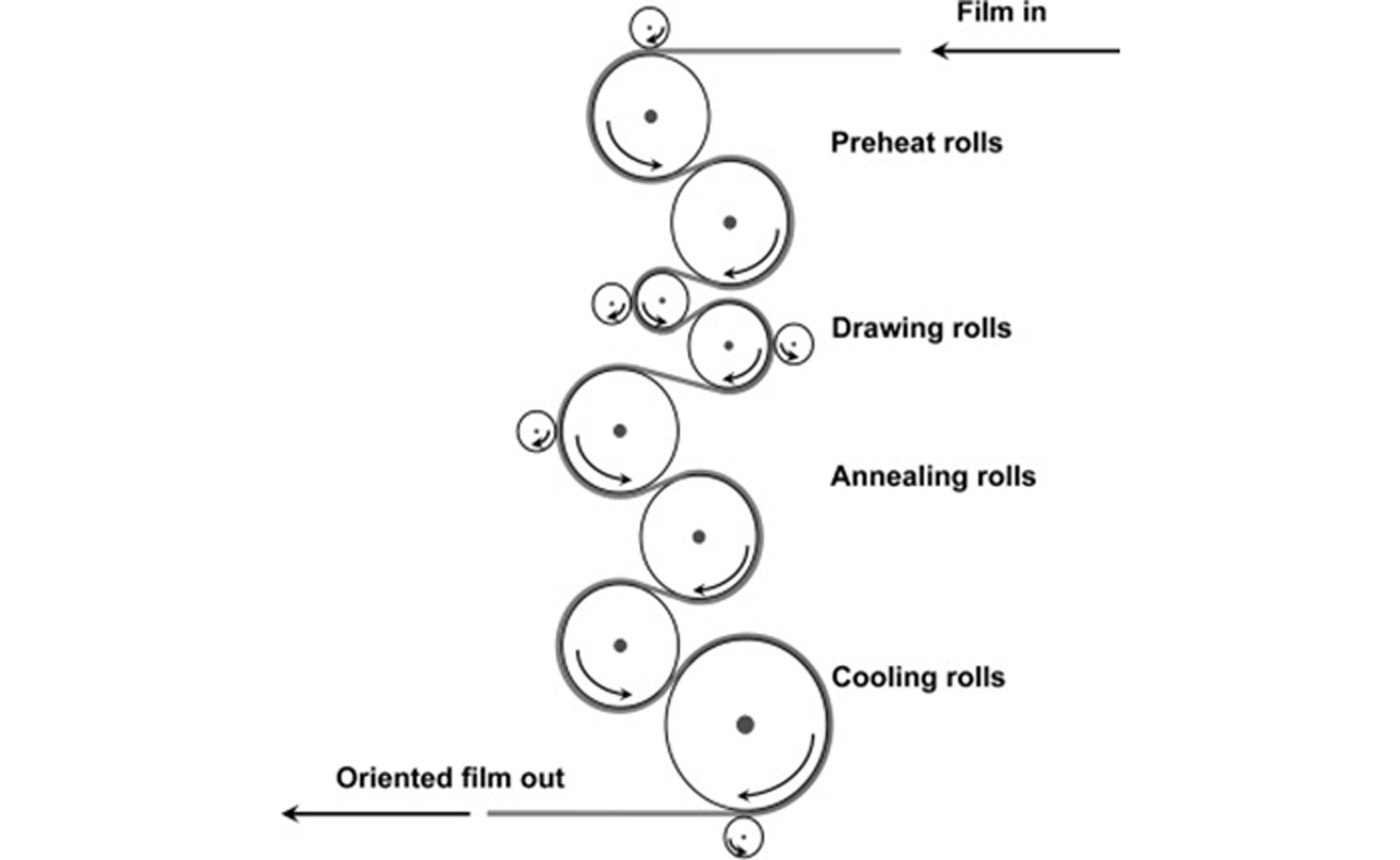

Asynchronous stretching involves two processes: Machine Direction Orientation (MDO) and Transverse Direction Orientation (TDO). One of the most typical examples is BOPP (Biaxially Oriented Polypropylene), where the film is first stretched in the machine direction and then in the transverse direction. This method is relatively easy to operate, and the product properties are easily controllable. Necessary heating and cooling treatments can be completed on the same stretching machine after stretching.

However, the thermal treatment during transverse stretching may damage the longitudinal orientation of polymer molecules. This makes it challenging to produce films with significantly higher mechanical properties in the longitudinal direction than in the transverse direction, or films with zero longitudinal thermal shrinkage.

The biaxial stretching process allows polymers to form small crystals and develop spherulites along the stretching direction, thereby improving the film's toughness. This process significantly enhances the film's tensile strength, gloss, hardness, barrier properties, and other performance characteristics.

1.BOPP

Which stands for Biaxially Oriented Polypropylene film, possesses several advantages, including lightweight, non-toxicity, odorlessness, moisture resistance, high mechanical strength, good dimensional stability, and excellent printing properties. It is widely used in the packaging of food, personal care products, cigarettes, tea, fruit juices, textiles, and more.

The general production process of BOPP involves raw material preparation, melting and extrusion, filtration, longitudinal stretching, transverse stretching, corona treatment, winding, annealing, and slitting into finished products. By employing step-by-step biaxial stretching, BOPP films with thickness ranging from 10 to 60 micrometers can be produced.

BOPP films exhibit high transparency, good glossiness, excellent water resistance, high stiffness, and good heat resistance. They are suitable for various applications, although they may experience slight shrinkage during heat sealing, which can be advantageous in applications such as heat-shrinkable cigarette wrapping films.

Additionally, BOPP films offer exceptional printing effects, with representative physical properties including low haze (less than 1.5%), glossiness greater than 85%, tensile strength (longitudinal/transverse) exceeding 120/20 MPa, elongation at break (<180%/65%), and an elastic modulus ranging from 1700 to 2500 MPa. The brittleness temperature is -50°C.

While BOPP serves as an effective moisture barrier, its oxygen barrier properties are relatively poor. Several industrial methods, such as aluminum metallization and aluminum oxide deposition, are employed to enhance its oxygen barrier performance.

2.BOPA

Biaxially Oriented Polyamide film, is known for its high strength, excellent gloss, low haze, outstanding toughness, and puncture resistance. It exhibits moderate gas barrier properties and excellent aroma retention. BOPA films find wide applications in the packaging of food processing, pharmaceuticals, chemical products, electronic products, and daily essentials. They are particularly suitable for frozen packaging, vacuum packaging, and cooking packaging, offering superior freshness and aroma preservation capabilities compared to BOPP.

The production of BOPA films can be achieved through either the tubular film method or the flat film method. The tubular film method involves double-bubble blowing, and in the film method, both synchronous stretching and asynchronous stretching can be employed.

Different processes result in variations in the physical properties of nylon films produced:

The physical properties of nylon films produced by different processes are as follows

| Film Type | Tensile Strength MD/TD (N/mm2) | Elastic Modulus MD/TD (N/mm2) | Shrinkage MD/TD (%) | Stretch Ratio MD/TD |

| Cast Film | 70~110 | 600/850 | <3 | - |

| Blown Film (Unstretched) | 95/90 | 1600/1600 | 5/1.0 | - |

| Double-Bubble | 220/190 | 2500/2300 | 1.5/1.0 | 2.7/12.5 |

| Two-Step | 250/260 | 3500/3000 | 1.4/0.8 | 3.0/3.3 |

| Synchronous (Mechanical) | 250/270 | 3600/3500 | 1.0/0.8 | 3.3/3.3 |

| Synchronous (Linear Motor) | 350/350 | 3700/3700 | 0/0.0 | 3.0-3.5/3.0-3.5 |

Comparison of Performance between Biaxially Oriented Nylon Film (BOPA), Biaxially Oriented Polypropylene (BOPP), and Biaxially Oriented Polyester (BOPET):

Performance comparison of different films

| Property | BOPA | BOPP | BOPET |

| Tensile Strength (MPa) | 196 ~ 245 | 127 ~ 294 | 157 ~ 245 |

| Elastic Modulus (MPa) | 1372 ~ 2150 | 1960 ~ 2940 | 3920 ~ 4900 |

| Tear Strength (KN/m) | 7.86 ~ 10.8 | 1.54 ~ 5.79 | 3.86 ~ 7.72 |

| Impact Strength (kJ/m) | 96.5 | 14.9 | 96.5 |

| Haze (%) | 0.078 | 0.039 ~ 0.078 | 0.039 ~ 0.195 |

| Thermal Shrinkage at 100°C (10μm) (%) | 2 | 0-8 | - |

| Operating Temperature (°C) | 60 ~ 130 | -50 ~ 130 | -70 ~ 150 |

| Water Vapor Permeability at 40°C 90% RH [0.1g mm/(d·m3)] | 40 | 1.5 | 5.5 |

| Oxygen Permeability at 28°C 0.1% MPa [0.1·mm/(d·m)] | 6 | 240 | 9 |

BOPA with moderate barrier properties can be enhanced in terms of oxygen resistance through PVDC (Polyvinylidene Chloride) coating. However, due to environmental considerations, these barrier materials have been replaced by alternative films.

Statement: This article is written by LD PACK and all rights reserved by LD PACK. The content is for reference only. Please correct any errors. Shall not be reproduced without permission, otherwise LD PACK will reserve the right to pursue its legal liability. If you have any technical questions, please email sales@ldpack.com for a discussion.