Analysis on the Causes of Uneven Rolling of Composite Film

In the production process of composite film, uneven rolling under various situations occur occasionally.

1. Uneven rolling and common causes:

Uneven rolling happens everywhere, often manifested as:

① Uneven rolling when rewinding after lamination

② Uneven rolling when getting off the machine

③ Uneven rolling when curing

④ Uneven rolling when getting out of the curing room

⑤ Uneven rolling when slitting

There are some common causes for the uneven rolling in these different processes, including:

(1) A large thickness difference of the film materials (mainly concentrated in the inner heat sealing film)

(2) Affected by Uneven thickness of printing pattern ink layer

(3) Uneven rewinding tension, uneven pressure of composite roller and uneven pressure of rewinding roller

(4) the influence of the precipitation and migration of the smooth agent.

2. Specific causes

(1) Uneven rolling ①, ② basically caused by one or some of above common causes

(2) Besides the common causes, the uneven rolling ③ is also related to the type of heating and the placement of the film in the curing room,which will cause by the uneven heating.

(3) Besides the common causes, the uneven rolling ④ is the result of the reverse action of phenomenon ③ after cooling

(4) Besides the common causes, the uneven rolling ⑤ may happen when slitting. For a big roll of film, Basically, the deformation at both ends is large and the deformation in the middle is small. After cutting, the inner stress of both ends of the film is greater than the friction between the layers of film, which resulting in uneven rolling sometimes when a whole roll of film is being slit or after slit.

When slitting, the uneven rolling is also related to the placement time after taking out of curing room.

Any problem is often caused by the joint action of several reasons, the uneven rolling issue is even more so. The cause of uneven rolling is a controversial topic. But the front-lines technical engineers are best qualified to speak on this question. In the analysis of all the reasons above, adhesive is not involved, which is an important material in laminating process.

3. Effect of adhesive on uneven rolling

First of all, any kind of adhesive will have a more or less effect on the friction coefficient of the composite film (actually the effect on the smoothing agent). However, this effect is often to increase the friction coefficient of the composite film, and the increase of friction coefficient is beneficial to prevent uneven rolling. So in the above analysis of the causes of uneven rolling, the adhesive is not included.

Secondly, in the actual operation, with other conditions fixed, replacing a adhesive or changing the amount of glue (generally reducing) can help to solve the problem of uneven rolling.

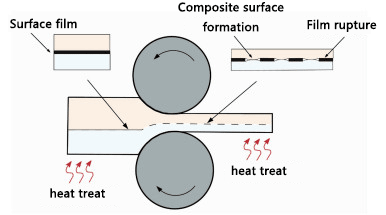

In the present way of lamination, the solvent-based dry lamination and the solvent-free lamination have been common, and must be understood separately.

Let's first discuss the effect of solvent-free laminating adhesives on uneven rolling

(1) For solvent-free lamination, there is indeed a low initial viscosity, under the action of the above "common causes", the adhesive coating plays the role of "lubricant". However, it is at most in phenomena ① and ②, and usually doesn't work in phenomena ③, ④and⑤.

(2) If it is the effect of "lubricant" due to low initial viscosity, then it is little to do with the slight changes of the glue on the minimum amount of coating.

(3) It is less likely that the uneven rolling happens due to the large deviation of glue amount on the left and right side. Because the amount of glue using in solvent-free lamination has been greatly reduced than that in solvent-based dry lamination, and the accuracy control is also very good, almost unlikely to appear the large deviation of glue amount on the left and right side. (It needs to discuss separately if the quality performance of the equipment is too low).

(4) If changing the amount of glue on solvent-free adhesive or replacing the adhesive can solve the issue of uneven rolling, then the real reason is that different type of adhesive or changing the amount of the same adhesive have an effect on the smoothness of laminated film, thereby changing the friction coefficient of the laminated film.

Note: Although the adhesive plays a role of “lubricant” due to the low initial viscosity in the solvent-free lamination, but so far there is no clear proof that uneven rolling refer to the lateral displacement happening in the adhesive layer between two laminated films, which is true remains to be proved.

Let's analyze and discuss the role of solvent-based adhesives in the uneven rolling.

(1) First of all, the initial adhesion of solvent-based adhesives is much higher than that of solvent-free adhesives, and there is basically no lubrication.

(2) The large deviation of glue amount on the left and right sides should be a serious operation error, but not the main reason of uneven rolling, which is not within the scope of the causes analysis and discussion.(like the presence of mosquitoes and hair in lamination, which should not happen.) Compared with solvent-free adhesives, the effect of solvent-based adhesives on the smoothing agents of laminated film is much smaller (except the solvent-based polyether adhesives). In other words, there will be less impact on the change of friction between layers.

4. Conclusion

In summary, no matter solvent-based adhesives or solvent-free adhesives, the impact on the causes of uneven rolling is minimal, which can be really quite negligible compared with the "common causes" and "specific causes". If you must find out the influence factor of the adhesive, it is mentioned above: any kind of adhesive will have more or less impact on the friction of the film surface. So the adhesive is not the main reason of the phenomenon of uneven rolling.

Why not add the change in velocity and tension into the causes of the uneven rolling during two parts analysis and discussion above? Because they are appearances, not causes!

Statement: This article is written by LD PACK and all rights reserved by LD PACK. The content is for reference only. Please correct any errors. Shall not be reproduced without permission, otherwise LD PACK will reserve the right to pursue its legal liability. If you have any technical questions, please email sales@ldpack.com for a discussion.

Article From: < PACKAGING FOREFRONT>