Mono Materials Application in Laminated Flexible Packaging

LD PACKAGING CO., LTD

Mr. Zhang Fenghui R&D Director

LD PACKAGING CO., LTD(shortened to LD PACK) is continuing to make unremitting efforts in research and development of recyclable packaging. As early as 2014, when the BOPE was introduced, LD PACK successfully developed mono-PE structure and launched a recyclable slider zipper pouch.

In recent years, with the increasing requirements of environmental protection and circular economy at home and abroad, LD PACK set up a R&D team for recyclable packaging and carried out the research and development of recyclable packaging products. After over two years of efforts, it successfully developed a series of mono-material recyclable packaging products, and gradually put into the market in batches, making social contributions to environmental protection.

Mr. Zhang introduced the development process and application of LD PACK’s recyclable packaging series in details.

The traditional flexible packaging generally adopts multilayer laminated structure with materials of PET, NY, PP, PE etc. Each materials are hard to separate and sort from the laminated film after use. Therefore, it’s also difficult to recycle. So packaging products made of mono PE or mono PP are easy to sort and recycle after consumption.

Here, we need to make two definitions clear firstly.

Sortability: an assessment of whether the structure can be identified and sorted into an appropriate material stream using current technologies and processes in an industrial scale sorting facility.

Recyclability: an assessment of whether the structure can be mechanically recycled using standard processes and technologies on an industrial scale.

At present, the problems to be solved when using mono materials include:

• Heat resistance: Ensure the film quality for automatic high speed packaging and pouch-making

• Flatness: Ensure the good effect of high speed automatic printing and product filling

• Stiffness & Strength: Ensure the standing-up performance and impact strength of products

• Barrier: Ensure the shelf life of the contents

• Heat Sealability: Good heat sealability to ensure the quality of automatic roll film and pouch making.

In response to these five major problems, with raw material modification, equipment transformation and process improvement, LD PACK has developed a series of recyclable packaging products including mono PE packaging, mono PP packaging, and large capacity packaging etc., which have been applied in batches.

1.Mono PE recyclable packaging

For packaging of common dry food, it can use 100% PE (PE/PE) structure; adding very small amount of EVOH can improve the barrier: PE\EVOH\PE(High Barrier).

The outer layer is made of heat resisting and tensile PE for printing, and the laminating layer is made of materials with high stiffness and good strength to ensure the flatness and strength of the pouch. It is suitable for stand up pouch, spouted pouch, stand up zipper pouch, flat bottom zipper pouch and four side seal zipper pouch etc.

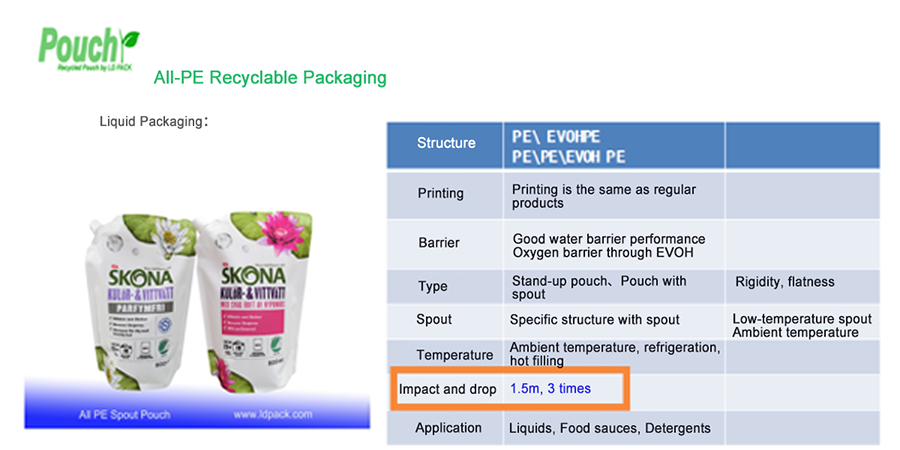

For liquid packaging, it can use 100% PE structure to balance the demands of heat seal strength, standing effect and drop impact, meeting the requirement of liquid packaging. High barrier structure is also suitable of food packaging. It is available for stand up pouch, spouted stand up pouch with capacity of 100-3000g.

2.Mono PP recyclable packaging

PP Spouted Pouch:

• 100% PP;

• The outer layer is resistant to temperature and shrinkage;

• Inner layer is with low temperature heat sealing and impact resistance;

• It is suitable for hot filling and cold storage, as well as packaging of daily products with high barrier;

• It is available for capacity of 70-150g;

• It is available for spouted stand up pouch and four side seal spouted pouch etc.

Mono PP Pouch:

• With 100% PP structure, it meets the high barrier requirement. Outer layer is made of PP with high heat resistant performance; inner layer is made of materials with good toughness and impact resistance.

• Capacity range: 500g~3Kg;

• It is available for stand up zipper pouch, flat bottom zipper pouch etc.

• Common Structure: OPP//OPP//CPP; OPP//CPP; OPP//MOPP(ALOXOPP)//CPP......

• Inside printing can use matt varnish (grit finish is not available yet) with same printing effect as regular products.

• Good water resistance and oxygen barrier can be improved via MOPP or ALOXOPP.

• It is available for room temperature storage and cold storage, but not sterilizing.

• It is suitable for lightweight packaging of dry food, pet food, biscuit, coffee, no more than 3kg.

Large capacity recyclable packaging:

Drop resistant: maximum 15kg from high of 1.2m for 5 times

A

A recyclable series of automatic packaging roll stock, such as mono PET packaging, adopts high barrier mono APET as bottom film and laminated PET as lidding film, with performance of barrier, easy to tear, anti-fog. It is suitable for packaging of fresh meat.

Statement: This article is written by LD PACK and all rights reserved by LD PACK. The content is for reference only. Please correct any errors. Shall not be reproduced without permission, otherwise LD PACK will reserve the right to pursue its legal liability. If you have any technical questions, please email sales@ldpack.com for a discussion.

Article From: < PACKAGING FOREFRONT>-LD PACK co.ltd