OPE Film in Flexible Packaging: Three Processing Paths

In the realm of flexible packaging, there's a growing interest in single-material recyclable packaging, with MDO-PE (Machine Direction Oriented Polyethylene) emerging as a hot topic.

Achieving a Mono-material replacement for traditional composite film structures requires PE to meet specific criteria during printing and lamination, including stiffness, flatness, printability, peel strength, and aesthetics. For bag-making, it must satisfy requirements for heat sealing integrity, heat resistance, and production line speeds.

Consequently, film manufacturers are modifying PE properties. Among these, BOPE (Biaxially Oriented Polyethylene) stands out as the earliest and most closely watched product, already finding practical applications.

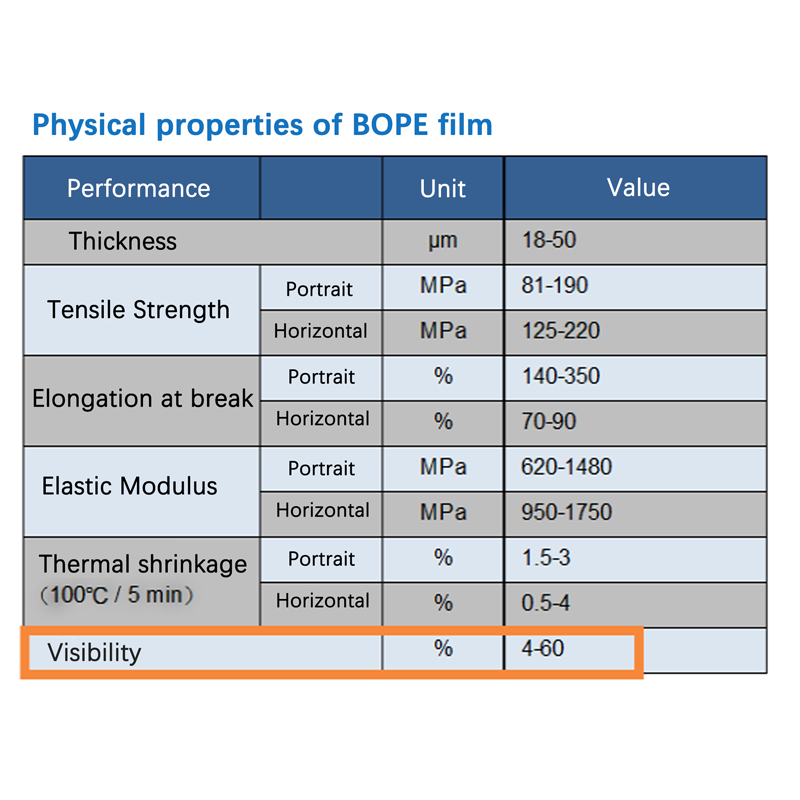

Here's a look at BOPE's data:

In many aspects, BOPE meets usage requirements well, but it falls slightly short in transparency and tends to shrink and deform during heat sealing, posing a bottleneck issue in bag-making. However, a long-standing product that has matured in various industries is gaining attention: MDO-PE (Machine Direction Oriented Polyethylene).

This article delves into the characteristics of products produced by three processes: extrusion coating + MDO, blown film + MDO, and extrusion coating + MDO + TDO (BOPE film). It points out that extrusion coating + MDO-PE is the most suitable product for flexible packaging companies. The standout feature of extrusion coating is its minimal heat sealing shrinkage and deformation, which are precisely the drawbacks of the other two methods and a pain point in the bag-making industry. Extrusion coating + MDO-PE fulfills requirements in printing, lamination, and bag-making processes.

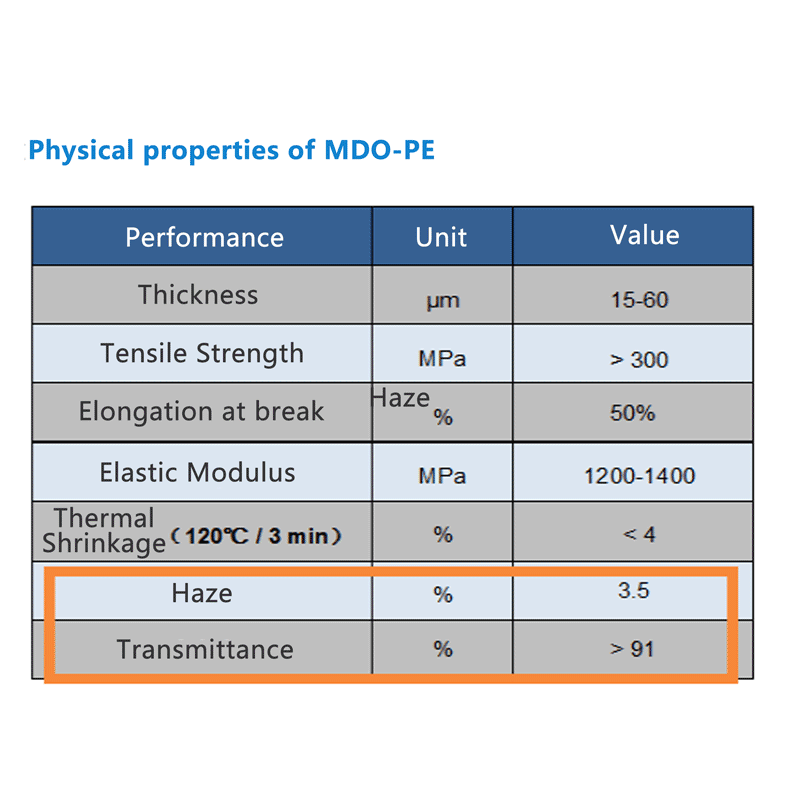

MDO-PE film possesses the following advantages:

1.High Strength and Rigidity:

As a printing layer, it meets the basic requirements of flexible packaging materials.

2.Excellent Printability:

Low haze.

Uniform thickness (< 1.5%).

3.Outstanding Heat Resistance:

Thermal shrinkage rate: at 120°C for 3 minutes, MD < 4%, TD ≤ 0%.

These attributes make MDO-PE film suitable for various flexible packaging applications, ensuring both structural integrity and aesthetic appeal.

Statement: This article is written by LD PACK and all rights reserved by LD PACK. The content is for reference only. Please correct any errors. Shall not be reproduced without permission, otherwise LD PACK will reserve the right to pursue its legal liability. If you have any technical questions, please email sales@ldpack.com for a discussion.

Article From: < PACKAGING FOREFRONT>