How does the Circular Economy of Flexible Packaging Work?

At present, flexible packaging has been widely used in food, medicine, cosmetics,daily necessities and other applications. The recycling and utilization of consumer flexible plastic packaging has become the focus of global social attention.The potential for developing a plastic circular economy is obviously huge. The world has been started and dedicated to the sustainable development rapidly.

These 5 steps have been endorsed by the European Sustainable Organization stakeholders together with a set of actions needed by each part of the flexible packaging value chain.

① Drive collection of All flexible packaging for sorting and recycling

② Sort and recycle the suitable mono-material fractions

③ Redesign multi-material flexible packaging to mono-materials with existing recycling streams where possible

④ Identity solutions develop capabilities to sort and recycle the remaining fractions

⑤ End markets for all recycled flexible packaging materials

Sustainable Packaging Design

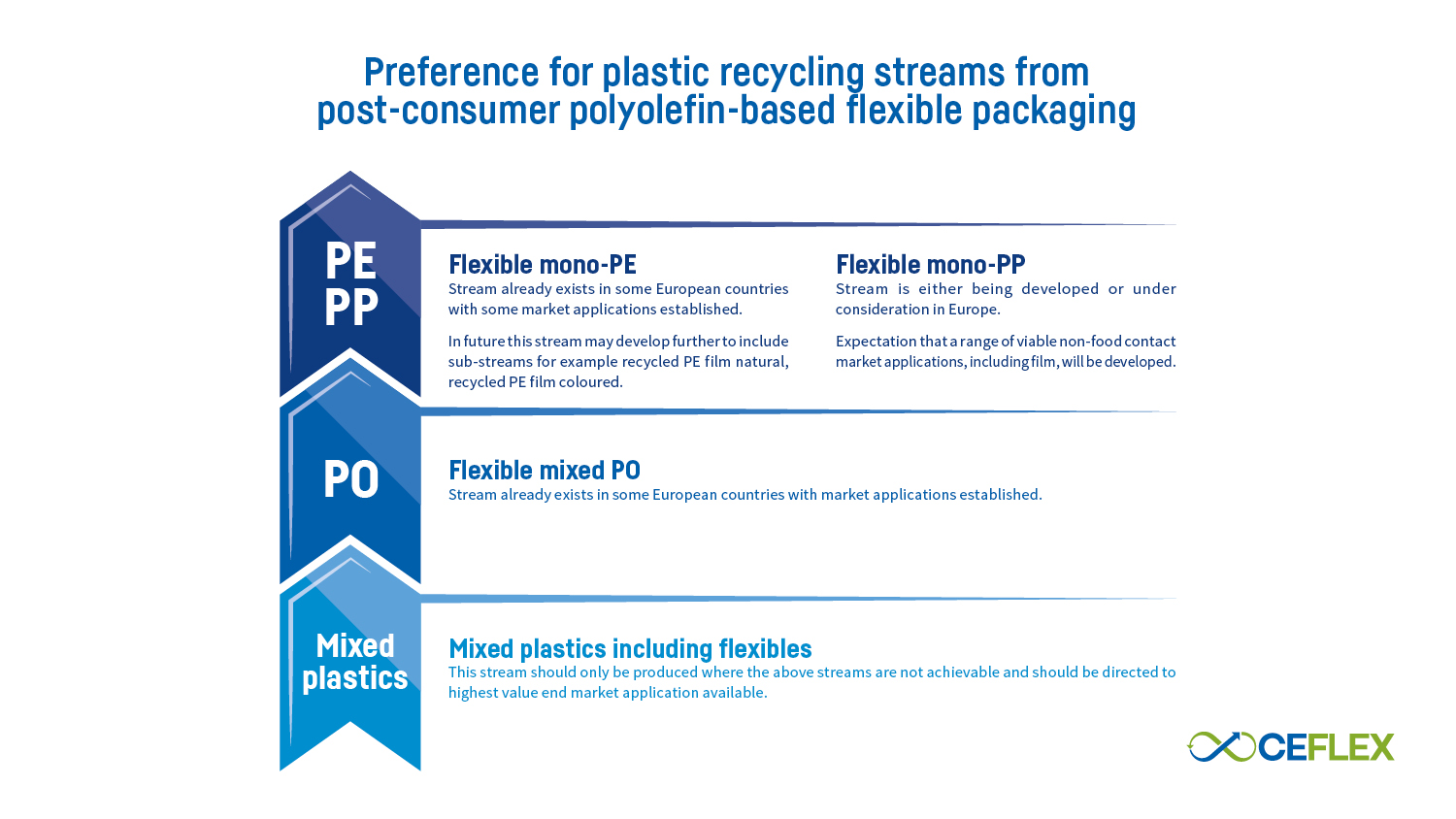

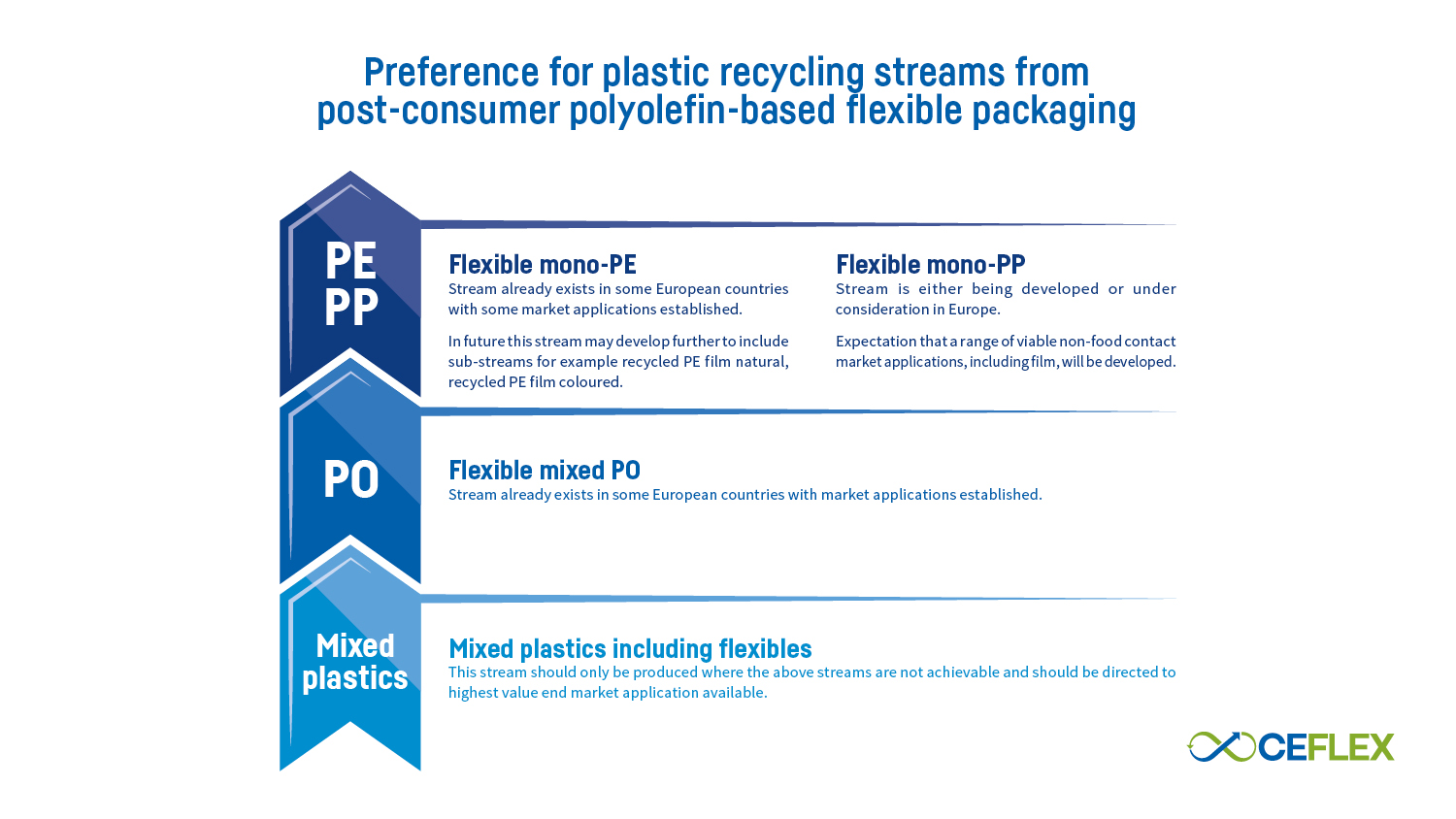

PP/PE/Polyolefin(PP-PE mixture) have been recognized as sustainable packaging materials by European Sustainable Organization.

How can LD PACK help you to embrace sustainable flexible packaging?

Focused on Sustainability

LD PACK is committed to developing sustainable, recyclable flexible packaging solutions.

Dedicated R&D Team

In response to rising global demand for environmental protection, we've formed a specialized R&D team for recyclable packaging.

Mono-material Design

Our mono-material structures improve recycling value and address the challenge of recycling traditional multi-layer flexible packaging.

- Mono-PE Packaging

- Mono-PP Packaging

- Polyolefin Based Packaging

- Mono-PET Packaging

Design for Circular Economy

Innovative structures help drive the transition from traditional composite materials to recyclable mono-materials—enabling high-quality reuse.

Easy to Switch

Our recyclable solutions are designed to integrate smoothly into your existing packaging lines, helping your brand stay compliant and eco-ready.