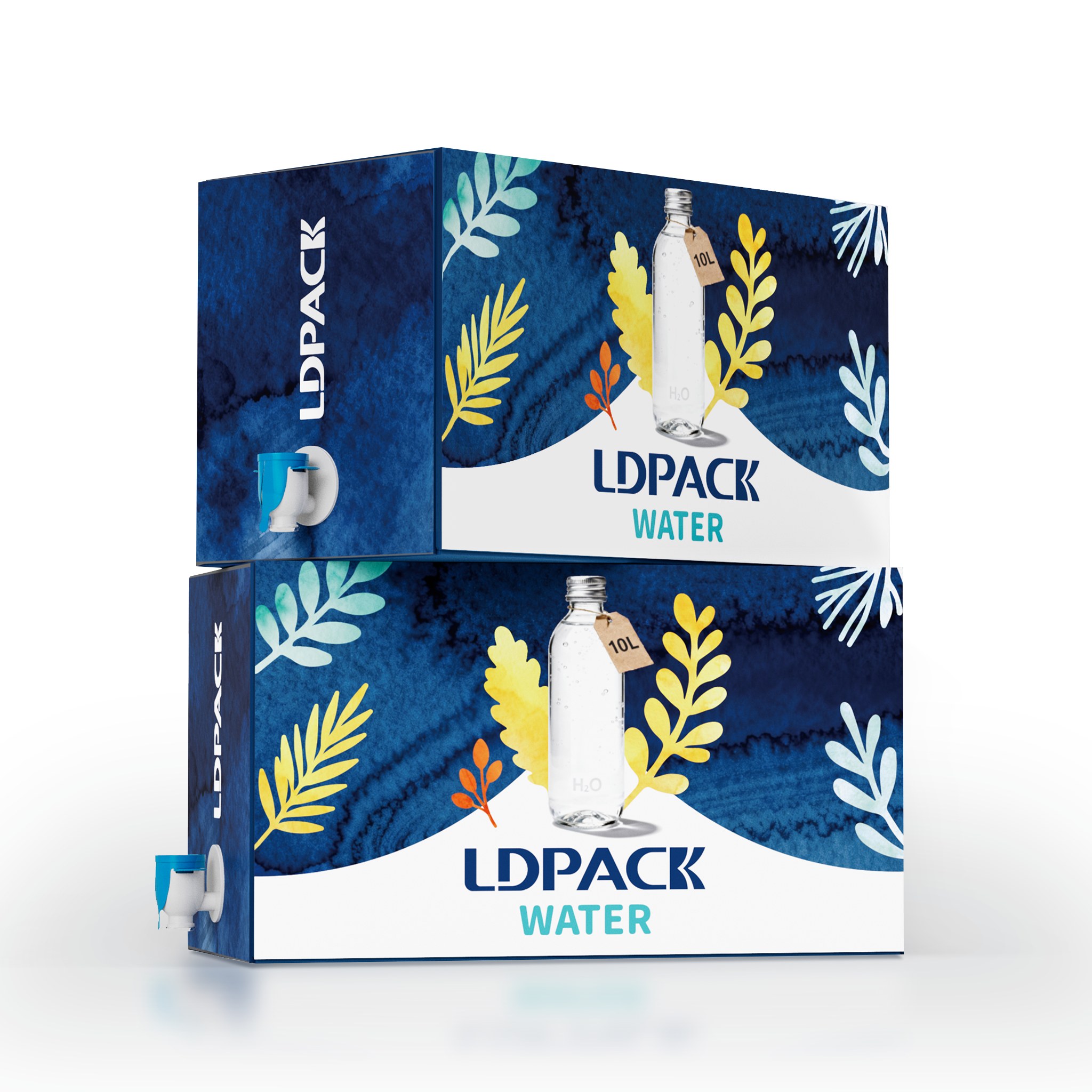

Bag-in-box (BIB)

Available in volumes ranging from 1 L to 220 L, our Bag-in-box solutions are designed to scale with your business, from small-format applications to large-volume liquid handling.

Applications

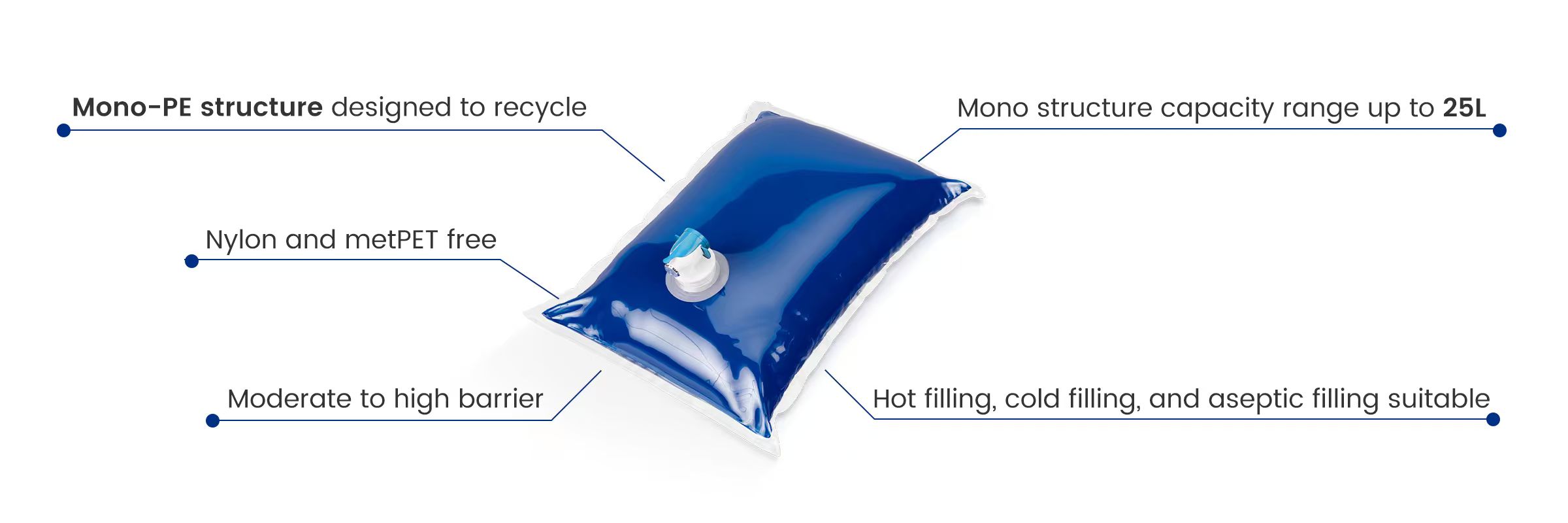

Features

- Multi-Layer Film: Excellent barrier for extended shelf life

- Built-in taps or spouts for easy dispensing

- Leak-Proof Construction: Secure seals for safe transport

- Perfect for bulk packaging of liquids

Benefits

- Flat-packed for easy storage and transport

- Cost-Effective: Lower material and shipping costs vs. rigid containers

- Eco-Friendly:Less plastic, recyclable outer box

Materials

- Available in standard and custom structures

- Standard Structure: with or Without Metallization

- Eco-Friendly Options: Mono-material PE

Bag-in-Box Packaging: Optimizing Efficiency and Sustainability

For over 35 years, we’ve been shaping the way liquid products are packaged and transported. Our deep industry expertise, paired with decades of experience, allows us to create solutions that don’t just meet your needs—they anticipate them. Whether you're working with retail, food service, or industrial sectors, our Bag-in-box packaging ensures that your products reach the market in the most efficient and sustainable way possible.

Tailored for Efficiency: Streamlined Logistics and Minimal Waste

Every aspect of our Bag-in-box packaging is designed to optimize your supply chain. From reduced transportation costs to smaller storage footprints, our packaging’s efficient design helps lower your overall logistics expenses. The flexible structure allows us to use less material while still providing the durability needed for safe transport, resulting in a higher product-to-package ratio that means more of your product, with less environmental impact. Additionally, Bag-in-box’s compact and flexible nature makes it an ideal solution for various distribution channels. Whether you're sending bulk orders to Food Service locations, offering family-sized packages for retail, or meeting the unique needs of industrial applications, our packaging ensures optimal space utilization across all stages of the supply chain.

Clean and Controlled: Precision in Every Dispense

Our Bag-in-box packaging ensures that your products are dispensed in the cleanest, most efficient manner possible. Thanks to our state-of-the-art fitment and connector systems, every drop of product can be dispensed with over 99% evacuation, even for highly viscous liquids. The design of our systems keeps oxygen out, maintaining the integrity of your product and extending its shelf life without the need for preservatives. This level of precision not only reduces waste but also improves consistency, ensuring that your customers experience the same quality every time they use your product. Whether it’s a condiment at home or an industrial chemical, our packaging ensures that every drop counts, reducing operational waste and supporting your sustainability goals.

Sustainability: Mono Material Choices and Structural Logic

We further advance our bag-in-box packaging around mono-material structures, with a clear focus on simplifying material composition while maintaining the performance required for liquid packaging applications. By minimizing material complexity, the mono-structure approach supports recyclability alignment and makes the packaging system more compatible with existing recycling streams, depending on local infrastructure. At the same time, this structural simplicity is engineered to preserve essential properties such as strength, barrier performance, and dispensing reliability—ensuring that sustainability considerations do not come at the expense of functional performance. Rather than adding layers to solve isolated challenges, we approach bag-in-box as a material-efficient system, where structure, performance, and end-of-life considerations are developed together. This allows brands to move toward more circular packaging designs with confidence, while maintaining consistency across production, distribution, and use.