Retort Pouch

LD PACK’s retort pouches combine high heat resistance, superior barrier performance, and leak-proof sealing—perfect for ready meals. Trusted by top brands, customized with cutting-edge technology.

Applications

Features

- Heat Resistant: Withstands up to 121°C/30mins, ideal for pasteurization and high temperature Sterilization.

- Leak-Proof: Strong seals prevent spills during cooking.

- Food Safe: Complies with food-grade standards, safe at high temps.

- Easy to Use: Convenient for sealing, cooking, and storage.

Benefits

- No need to refrigerate or add preservatives to the packed food

- Taste, flavour and aroma of packed food remains intact

- Easy to handle, easy to open, easy to re-heat

- Reduced weight, storage space, and logistics cost

Materials

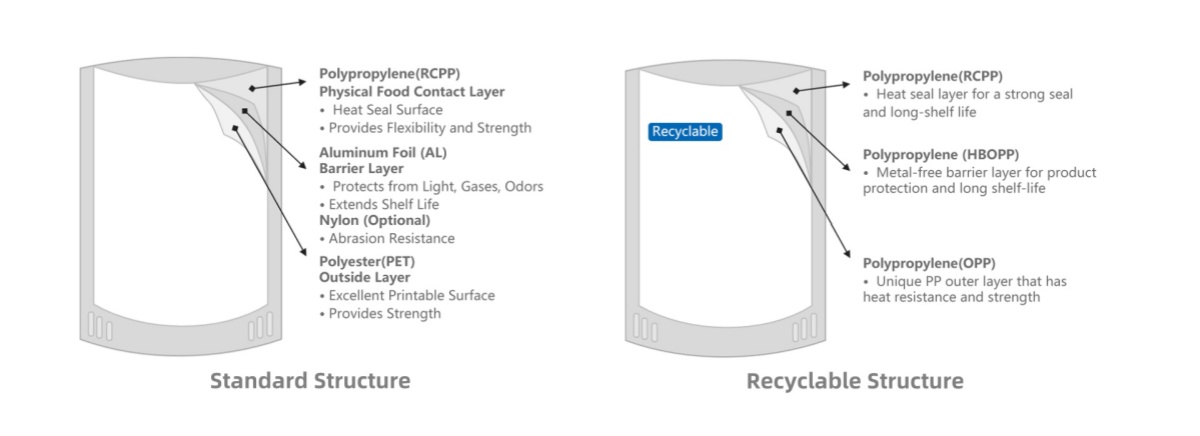

- Available in standard and custom structures

- Standard Structure: with or Without Metallization

- Eco-Friendly Options: Mono-material PP, Mixed Polyolefins

High Heat, Higher Standards

Retort pouch is a kind of laminated plastic film pouch that can be heated. It takes into account of the advantages of both canned containers and boiling water resistant plastic pouch. The food can be kept wholly intact in the pouch and heated by high temperature sterilization (generally in 120~135℃). Once taken out, it can be served. Retort pouch is not only convenient, hygienic and practical, but also greatly maintains the original flavour of the food. It is favoured by consumers.

- Retort pouch is a type of packaging suited to food that need to be heated and sterilized, regarded as a lightweight and economical alternative to industrial canning methods.

- With heat seal and vacuum seal, retort pouch is usually used for both hot and cold food packaging.

- Retort pouch has high barrier properties, including good oxygen and water vapor barriers, light and corrosion prevention.

LD PACK offers exceptional packaging solution that withstands aggressive retort conditions and excellent barrier properties.

Up to our high quality standard

√FDA approved food grade material

√ISO & QS quality grade

√Excellent printing

√Recyclable

The key drivers of Retort Pouch Market

- Benefits of retort pouch in food and beverages industry and increase in demand for lightweight as well as sustainable packaging are the key factors boosting the Retort Pouch market growth.

- Increase in E-commerce activities and food delivery services in the main driver of Retort Pouch market.

- The rise in public awareness about health issues is one of the factors propelling the Retort Pouch market throughout the forecast period. Increase in use of sterilizing solutions as a result of the coronavirus epidemic is also driving the demand for the overall industry.

- The rise in demand for retort pouch in pharmaceutical, and cosmetics drives the demand for retort pouch, owing to the fact that they help in easing the process of packaging and transit.