Advantages of multi-layer co-extruded film

Status & Prospect of Multi-layer Co-extruded High Barrier Film

Author: Guobing Zeng

Abstract: This article introduces the performance characteristics and application prospects of multi-layer co-extruded high barrier films, and make a point that the multi-layer cast film performs excellent barrier properties, mechanical properties, stretch forming properties and heat sealing properties, as well as advantages of low production cost, simple process, low energy consumption and high production efficiency, which meets the requirements of environmental protection and has good development and application prospects.

With the rapid development of the global economy and the increasing competition in the market, consumers have gradually increased the functional requirements of plastic film. The traditional mono material film has been unable to meet the needs of consumers, and multi-layer co-extrusion film integrated a variety of functions has been rapidly developed. In addition, with the increasing demand for social environmental protection, the generation of waste should be reduced under the premise of meeting the packaging function. Multi-layer co-extrusion film is in line with the development trend of global environment protection due to its advantages of low cost, simple operation, almost no environmental pollution and reuse. Several world’s large film equipment enterprises (such as WH, Refin from Germany, Collins March from Italy, Lenting from Austria, etc.) have released new technology of multi-layer consecutively, and the film will develop towards multi-layer structure in the future.

According to authoritative data, the co-extruded film occupies 38% of flexible packaging materials in developed countries while it’s less than 2% in China. And the multi-layer co-extrusion process can save nearly 20% of the cost compared with other laminating processes. Therefor, there is still a great room for development in the domestic market. With the rapid development of food, electronics, medical, chemical industry and the continuous rise of domestic labor costs, automatic packaging will increasingly replace manual packaging, which facilitates the favorable development of multi-layer co-extruded film.

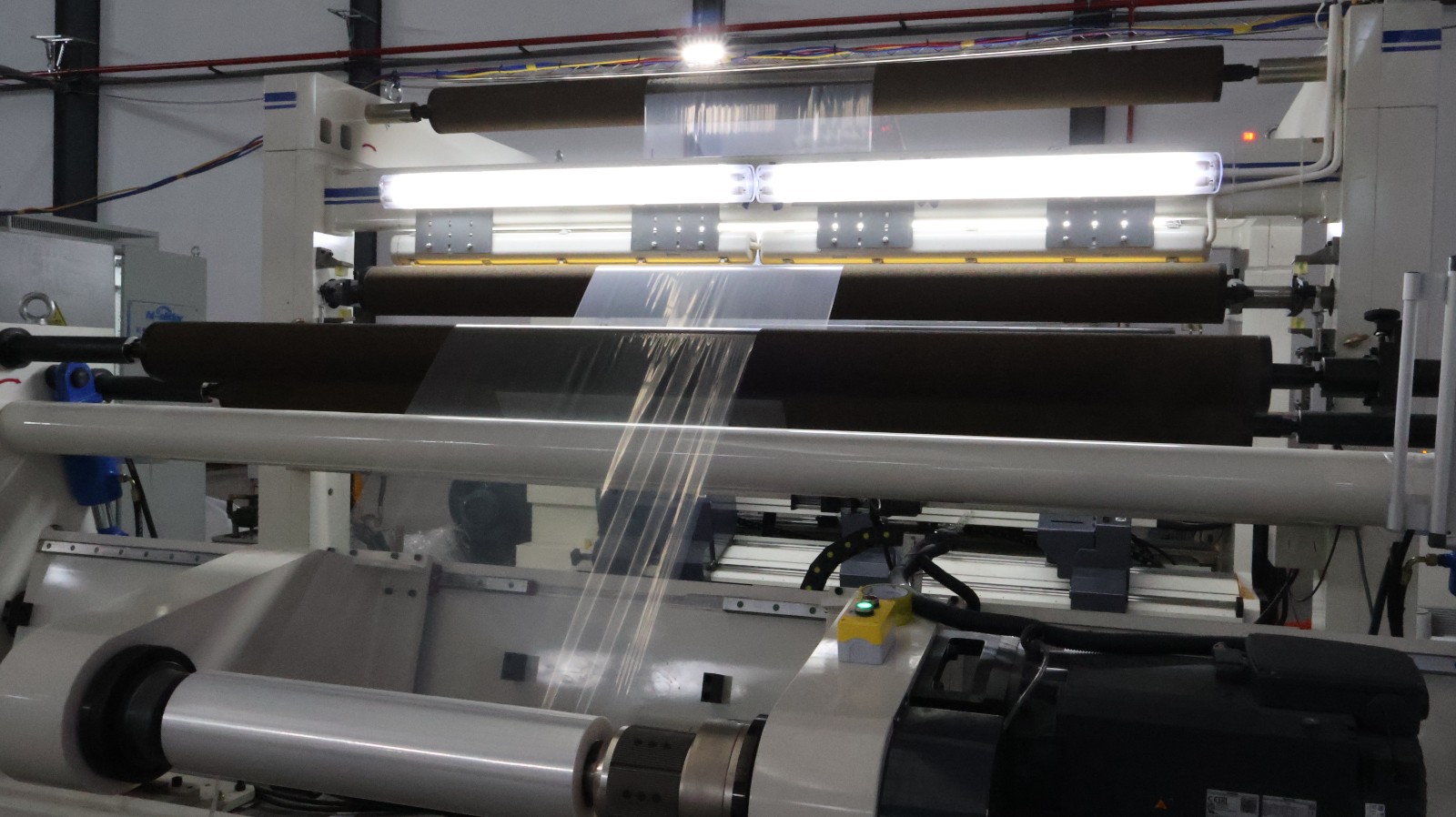

1. Advantages of multi-layer co-extruded film

Generally speaking, flexible packaging materials need to meet the following requirements:

1) Excellent oxygen barrier performance

2) Excellent water barrier performance

3) Excellent aroma preservation ability

4) Good heat sealing performance

5) Certain low temperature resistance

6) Certain heat resistance

7) Good printability

8) Good mechanical properties

9) Good optical performance

Meanwhile, the multi-layer co-extruded film is also outstanding in the following aspects:

a. Film formulation optimization is more reasonable and it is better to select materials;

b. Better film physical properties. Multi-layer film structure has better physical properties such as stretching resistance, puncture resistance and tear resistance than the few-layer film structure under the condition of same formula and resin proportion.

c. It is beneficial to improve the output of the film.

Statement: This article is written by LD PACK and all rights reserved by LD PACK. The content is for reference only. Please correct any errors. Shall not be reproduced without permission, otherwise LD PACK will reserve the right to pursue its legal liability. If you have any technical questions, please email sales@ldpack.com for a discussion.