Knowledge about Food Packaging - 2

Control of Environmental Factors in Food Packaging

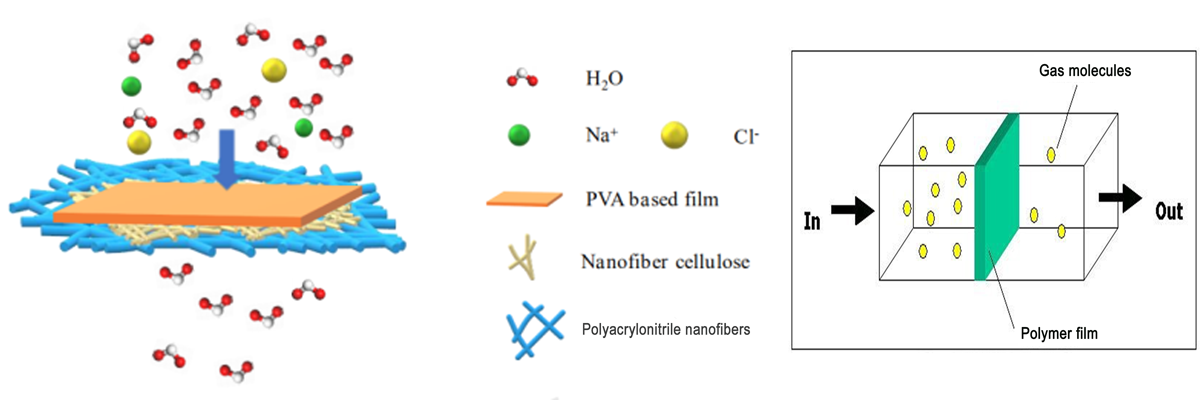

1. Gas Resistance

Gas resistance, also known as gas permeability, according to the definition of the Chinese standard GB*T1038-200- "The gas permeability test method - differential pressure method of plastic film and sheet", gas transmittance refers to the gas volume through unit area of the sample in the unit time under a constant temperature and unit pressure difference. They are expressed as value of volume at standard temperature and pressure with unit of :cm3*m2·d·Pa. For the quality assurance in food circulation, gas resistance mainly refers to the ability to prevent O2, CO2 and N2 through the food packaging during circulation.

(1) Oxygen Resistance: if the packaging inside is under low oxygen, due to 21% of oxygen in the air, there is a partial pressure difference of oxygen on both sides of the composite film, so it is necessary to prevent the oxygen in the air (the side with high oxygen partial pressure) from entering the package (the side with low oxygen partial pressure) through the composite film.

(2) CO2 Resistance: For the Modified Atmosphere Packaging (MAP), the CO2 can inhibit the aerobic bacteria and facultational anaerobic bacteria in food, and has a certain antibacterial effect. If the proportion of CO2 in the packaging is high, over 20%, while the CO2 in the air is only 0.03%, the CO2 may go outside the packaging through the composite film. So it is necessary to maintain the proportion of CO2 in the packaging. For the ordinary plastic film, the rate of CO2 through the same piece of film is several times more than that of oxygen, that is to say, CO2 is easier to pass through the plastic film than oxygen. So for MAP, it is also very important to pay attention to the barrier of CO2.

(3) N2 Resistance: N2 is an inert gas, which has no effect on food quality. It is mainly used as a filling gas in MAP packaging to keep it in a certain shape and prevent it from collapsing. In general, there is no need to consider too much about the barrier performance of N2, because after ensuring that the composite film has strong O2 and CO2 resistance, the gas barrier will not be weak, and the content of N2 in the air is high, about 78%. Even if N2 in the air will pass through the film into the packaging, there is not so much impact on the overall shape of the package.

2. Moisture Resistance

Moisture resistance, also known as water vapor permeability, according to the definition of the Chinese standard GB*T 26253-2010 - "The infrared detector method of water vapor transmittance for Plastic films and sheets", water vapor transmittance refers to the amount of water vapor per unit time through the sample per unit area when the test reaches equilibrium under the specified test conditions. The unit is g*(m·24h).

If there is a relative humidity difference on both sides of the composite film, water vapor will enter the side with low relative humidity from the side with high relative humidity through the composite film to achieve humidity balance on both sides. Therefore, in the weather or environment with high relative humidity, when the relative humidity in the package is low, the food in the package may be affected by moisture and cause poor quality. On the contrary, when the food with high moisture content circulates in a low humidity environment, it may lose water and become worse.

3. Light Resistance

Light resistance, also known as transmittance, according to the national standard GBT 2410-2008 - "Transparent plastic transmittance and haze determination", refers to the ratio of the luminous flux through the material and the luminous flux on the material (%). For the food that is easy to be affected by light, the selection of light-avoiding and light-resistant packaging materials, or coating a light resistant layer on the composite film, or coloring when printing, can reduce the damage of light in circulation to food quality.

Food requirements for other features of composite film

1. Other Usage Requirements besides Barrier

In addition to the barrier properties such as gas resistance, moisture resistance and light resistance, food packaging also has other performance requirements of the composite film.

(1) Heat Sealing Performance

Heat sealing performance determines the speed of packaging sealing, the appearance of the seal, whether the seal is good, and whether the circulation will break the bag due to the extrusion and falling. The heat sealing is related to the high temperature resistance of the film. If it is very high temperature resistant, it is difficult to heat and seal, and it is not suitable for the inner layer material of the composite film. In addition, the heat sealing effect is also related to the temperature, pressure and heat sealing time of the heat sealing equipment. It is very important to set suitable parameters according to the characteristics of the film for the heat sealing effect.

(2) High/Low Temperature Resistance

High and low temperature resistance performance of the film is related to the heat sealing. Plus, many foods need high temperature sterilization at 121℃or 135℃, which requires the film to have high temperature resistance, otherwise the sealing cracking and other problems may occur. For the frozen food, the packaging film is necessary to have a certain low temperature resistance, otherwise it is easy to embrittling, cracking and other phenomena.

(3) Puncture Resistance

In production, many packaging bags are stacked together to move and fall on the line, and the sharp corners of the bags may puncture other bags. In the circulation process, the packaging bag may also be punctured by a sharp object when shaking or falling in the transportation, resulting in losses due to the food outflow or contamination.

(4) Oil Resistance

Many foods have high oil content, or are wrapped in oil. If the inner layer of the composite film is not oil resistant, the oil may pass through the inner layer into the binder between the inter layer of the composite film, reducing the bonding performance and causing the film to delaminate. More seriously, the oil that has been in contact with the binder may return to the food through the film, contaminating the food and endangering food safety.

2. Appearance

Packaging is beneficial for brand promotion, so the appearance of packaging will directly affect the consumers' purchase decision. With the improvement of living standards, people's spiritual needs are rising. They pay more attention to the appearance of packaging. The transparency, printing and stiffness mainly affect the appearance of packaging.

3. Cost

Because food involves people's livelihood and is a high-frequency FMCG product. Compared with many other products, food belongs to a class of goods with low price, which also determines the price of food packaging is relatively cheap, so cost control is one of the important factors that must be considered in the use of composite film. Because plastic resin is a by-product of petroleum, it is often affected by the fluctuation of petroleum prices, so that packaging enterprises have to face greater challenges in cost control.

4. Match with Equipment

When designing the structure of the composite film, the packaging manufacturer must also match the appropriate packaging composite film according to the sealing, sterilization, storage and transportation equipment conditions of the food production enterprise, and provide personalized packaging materials and related supporting services for the enterprises.

Performance Comparison of Commonly Used Materials for Food Flexible Packaging

Performance | BOPET | BOPP | BOPA (NY) | AL | MPET | MCPP | KPET | KOPP | PE | CPP | Paper |

Transparency | √ | √ | √ | X | X | X | O | O | O | √ | X |

Printing | √ | √ | √ | * | O | O | √ | √ | O | O | √ |

Fragrance Keeping | √ | X | O | √ | √ | √ | √ | √ | X | X | X |

Sealing | X | X | X | X | X | √ | X | X | √ | √ | X |

Stiffness | √ | O | * | √ | √ | O | √ | O | * | O | √ |

Low Temperature Resistance | √ | * | √ | √ | √ | * | √ | * | √ | X | √ |

High Temperature Resistance | √ | * | √ | √ | √ | O | √ | * | √ | √ | √ |

Puncture Resistance | O | O | √ | X | O | O | O | O | √ | O | X |

Oil Resistance | * | * | O | √ | O | O | * | * | O | √ | X |

Oxygen Resistance | O | X | O | √ | √ | √ | √ | √ | X | X | X |

Water Resistance | O | O | X | √ | √ | √ | √ | √ | O | O | X |

Packaging Applicability | √ | O | √ | √ | √ | √ | √ | √ | √ | √ | √ |

Price | General | General | Expensive | Expensive | More Expensive | More Expensive | More Expensive | More Expensive | General | General | Cheap |